Industrial Automation Solution

Vision Inspection System for Car Windshield and Tailgate Fixation

Project Overview

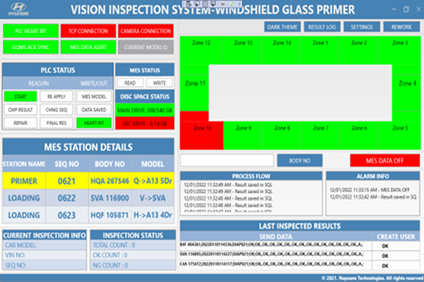

The Vision Inspection System ensures precision in the application of primer and sealant during car windshield and tailgate fixation. A bot applies primer at one station and sealant at the next, while a camera verifies the width and height of these applications, maintaining strict quality control.

Our vision software analyzes data sent by the camera to verify whether the width and height of the primer and sealant fall within set boundaries. If not, an alert is displayed on-screen, and the maintenance team is notified for immediate corrective action.

Key Features

Primer and Sealant Application Inspection

Using an Wenglor camera, the system accurately measures the width of the primer and both the width and height of the sealant, ensuring that each application adheres to required specifications.

Real-time Quality Analysis

Our software performs real-time analysis of the inspection data to immediately identify any deviations from quality standards, enhancing the reliability of the fixation process.

Automated Alerts and Notifications

If an application falls outside specified parameters, an on-screen alert is triggered, and the maintenance team is notified for prompt action, minimizing downtime and defects.

Technology Stack

Used: Vision Software, Wenglor Camera, Automated Bot, Real-time Monitoring and Alert System.