Industrial Automation Solution

2D Barcode Scanner and PLC Integration

Project Overview

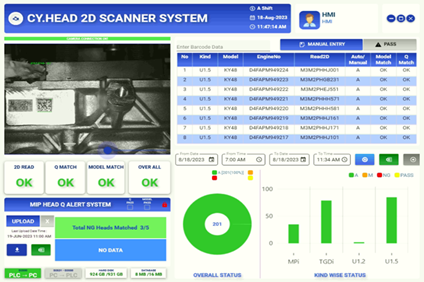

This program was designed and developed to provide a dashboard that visualizes 2D scanner barcode information and signals the PLC to make decisions in NG (No Good) scenarios.

A Cognex Data Matrix Scanner is installed in the station to scan the data matrix engraved in the rear cover of the transmission box. This ensures that the correct rear cup is fixed for the appropriate model, and it verifies vendor information.

Key Features

Scanner and Barcode Processing

The Cognex Data Matrix Scanner accurately reads the engraved data matrix codes, allowing the system to verify whether the correct part is installed.

PLC Integration

The system provides a signal to the PLC, enabling it to make real-time decisions based on barcode data, ensuring quality control during production.

Dashboard for Real-time Monitoring

A custom dashboard is developed to display the barcode information and provide insights into the scanning process, helping operators monitor and manage production quality.

NG Scenario Handling

In case of an NG scenario, the system immediately alerts the PLC, allowing quick corrective action, thus avoiding faulty assemblies and ensuring the proper functioning of the transmission box.

Technology Stack

Used: Cognex Data Matrix Scanner/Reader, PLC Integration, Custom Dashboard.